Product Feed Components

High Pressure Feed Systems – The high-pressure pump pressurizes the product to a specified pressure and delivers the product to the atomizing nozzle lance

Process Air Inlet System - Supplies pre-filtered air to the supply fan and burner system. Heated air is directed through an air disperser to ensure uniform distribution into the drying chamber.

Indirect Heater - Ideal for sanitary environments, our patented Indirect Heater delivers ultra-pure process air with no combustion byproducts or NOx contaminants.

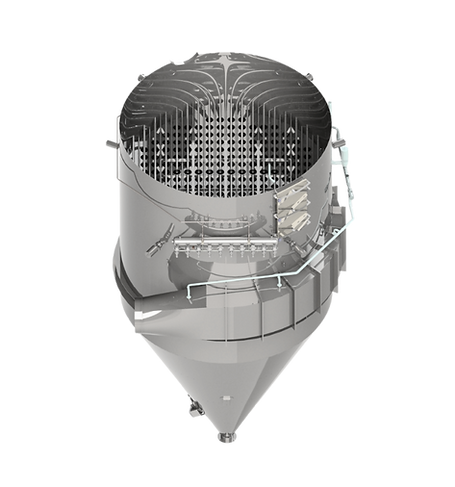

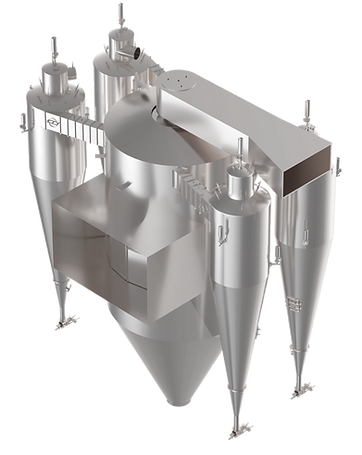

High Efficiency Cyclones – Utilize centrifugal force to separate the powder from process air. Powder exits the bottom of the cone while air exits through the vortex finder at the top.

Baghouse – Our standard baghouse system includes a walk-in plenum, efficient bag pulsing, overpressure vents, CIP isolation and pneumatic thumpers as needed.

Bag in Place (BIP) CIPable – Allows filter bags to be cleaned in place, matching the effectiveness of laundering. This system meets USDA and 3-A sanitary standards.

Wet Scrubber – Removes fine particles from the exhaust air streams to help meet strict environmental and emission regulations and reduce odors.

Crystallization Belt - Provides hold time in whole whey and whey permeate processing to ensure maximum post-crystallization and conversion of lactose. Includes automatic tracking, CIP, bottom drag, inspection ports, and manway doors, as necessary.

Sanitary Product Removal System - A sanitary, chain-driven product removal system that transfers powder in equipment such as box dryers, static fluid beds or crystallization belts.

Fluid Bed

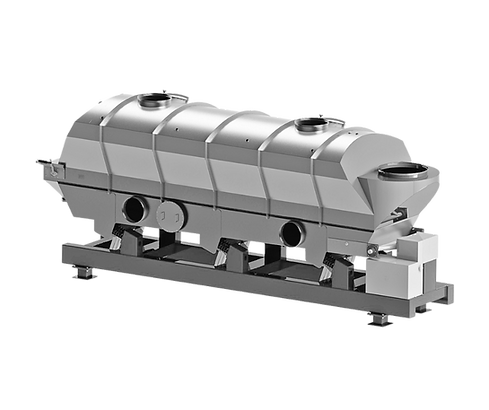

Vibratory Fluid Bed – An external vibratory fluid bed with up to 3 zones for product tempering, final drying, and cooling. Features include air actuated weirs, BFM fittings, CIP spray devices, customized screens, and inspection manways. Can be driven with the Dahmes no-weld transmission or vibratory motors.

Static Fluid Bed – Designed for product cooling and conditioning with adjustable weird, BFM fittings, CIP spray devices, water jet screens, and inspection manways. Customizable with an integrated, CIP’able baghouse for sticky products.

Safety & Protection Features

Over-Pressure Protection – Includes vent panels and suppression canisters to isolate and safely vent pressure in the event of a system incident.

Water Deluge – Integrated into the PLC and activated based on exhaust temperatures, this system delivers water to the dryer to prevent damage and injury.

Heat Recovery Systems

Heat Recovery - Constructed from continuously welded stainless steel, ensuring years of service in the most hostile process of exhaust streams.

-

Shell & Tube Design

-

Envelope Design

Clean-In-Place (CIP)

CIP Nozzles with routing valves and interconnecting piping to clean the drying system where necessary without disassembly.

Ready to optimize your spray drying system with precision-engineered components? Contact our team to learn how we can help with the efficiency, safety, and performance of your operations.

.png)